Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

+86-18820023218

Model No.: HTD-PT21E

Brand: HTD

Applicable Industry: Manufacturing Plant

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 6 Months

Core Components: Plc, Bearing, Motor

Old And New: New

Place Of Origin: China

Warranty Period: 1 Year

Service System: Video Technical Support, Online Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service

Zipper Material: Plastic

Packaging: Standard Package for Export

Productivity: 5000 SETS/ YEAR

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Supply Ability: 5000 SETS / Year

Certificate: CE

Port: Shenzhen,Guangzhou,Shanghai

Payment Type: L/C,T/T,D/P,D/A

Incoterm: FOB,CFR,CIF,EXW,FCA,DDP

PRODUCT DESCRIPTION

Model Name: Fully Automatic Electric zipper top stop injection molding and zipper cutting Machine

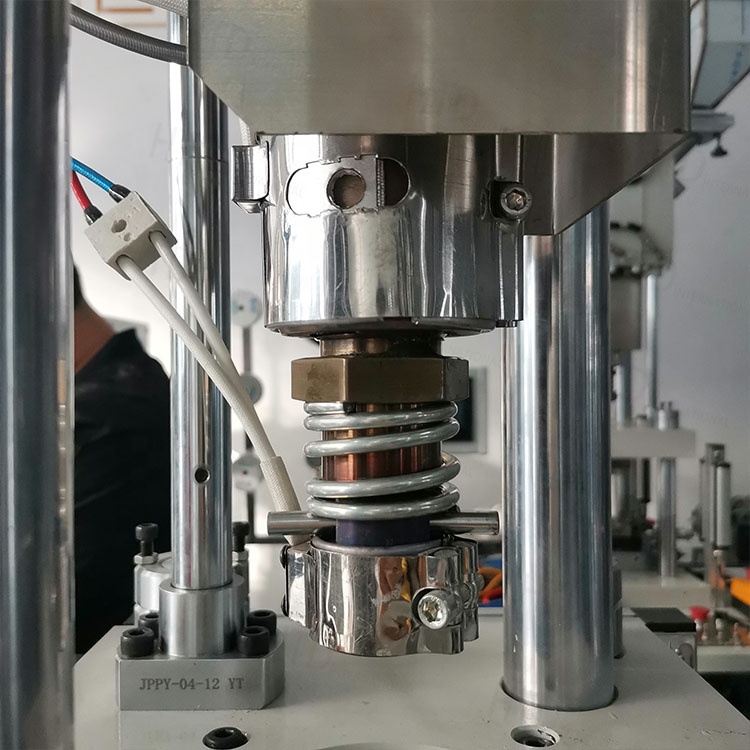

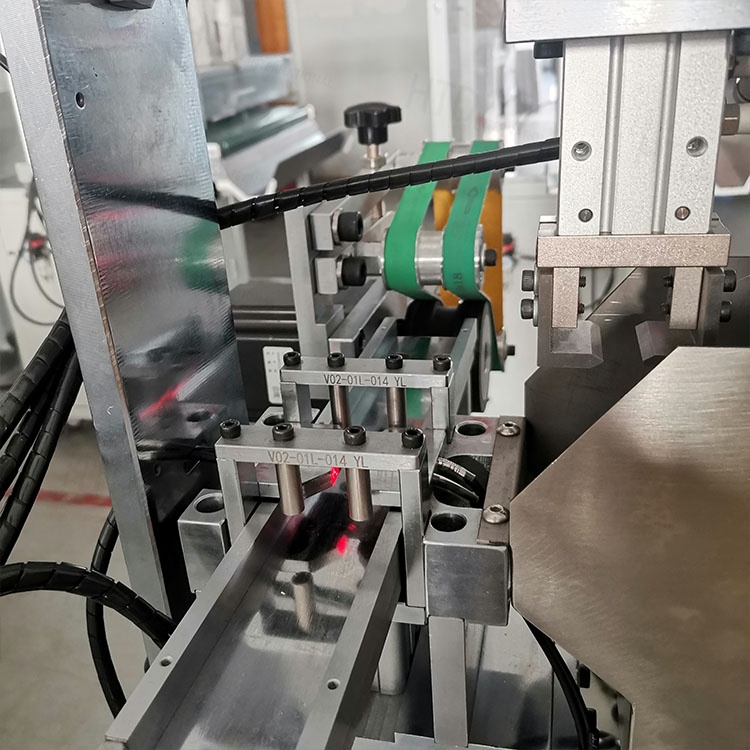

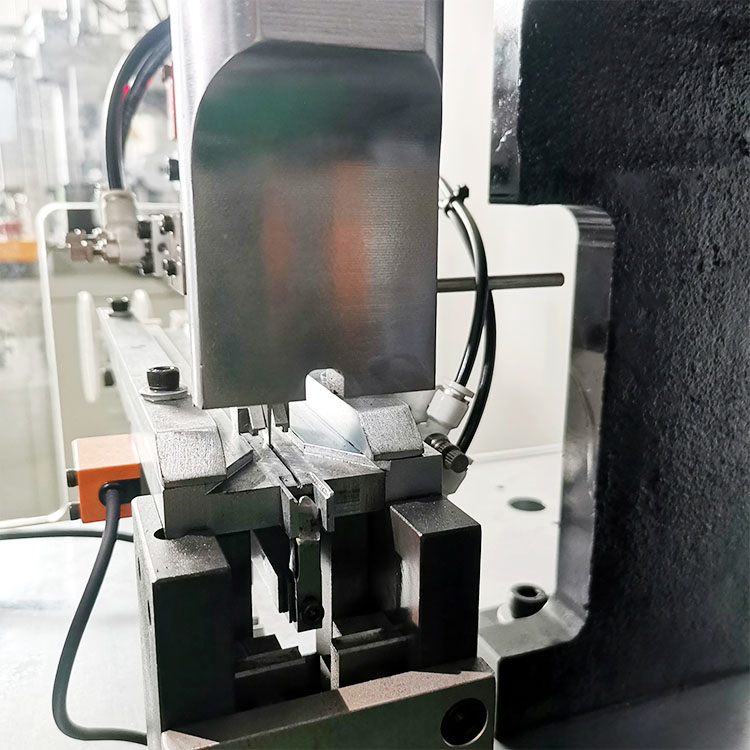

This new style machine combines zipper injection molding machine and cutting machine into 1 machine. The final production process for Delrin Zipper Making Machine.

1, One of the most toughest problem for Plastic Zipper Injection Machine is the oil leaking due to hydraulic oil system. This new style Zipper Machine is a solution to oil leakage and regular replacement of hydraulic oil of the traditional oil-pressure injecting machines, thus saving the cost and reducing the frequency of oil pollution cleaning!

2, Its speed can be up to 700 pcs/Hour, with the efficiency 10% higher than that of the traditional oil-pressure Resin Zipper Machine.

3, It enables quick production and vibrates only slightly when locking dies, with stable die locking pressure and a low product defect rate.

4, Suitable for both open-end zipper making and closed-end zipper making production process.

We offer free consulting for our main products, zipper machine. Contact us for more detail and Plastic Zipper Machine Price!

PARAMETER

| Capacity | 700pcs/60cm/hour |

| Power | 3.0 KW |

| Voltage | 380V |

| Frequency | 50~60HZ |

| Machine size (L*W*H, mm) | 2400*685*2000 |

| Net Weight | 800kg |

| Power Consumption | 2.5 kWh/H |

Image detail

Except for Plastic Zipper Machines, we have Metal Zipper Machines, Nylon Zipper Machines and Invisible Zipper Machines.

Our professional technical team is willing to offering consulting for all zipper production. Always looking forward to your contact!

OUR SERVICES

We provide door to door installing services worldwide.

We are always 24/7 online to help our customers to solve problem.

OUR ZIPPER MACHINE IN THE WORLD

Our Zipper Machines has been sold all around the world.

Many of our customers have become leaders in the zipper industry.

PACKAGING & LOADING

Vacuum packing and wooden crate, standard export packing.

Product Categories : Plastic Zipper Machines > Plastic Open-end Zipper Machines

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.